Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

Automatic Blow Molding Machine Manufacturers

2. Equipped with casting aluminum heater, temperature controlled by computer.

3. PLC program controls the machine operation swiftly and accurately.

4. Parison controller equipped on die head guarantees the wall thickness of bottle to be even.

5. Screw rotating speed can be adjusted by inverter in a wide range.

6. Special blowing design minimizes the wasted material.

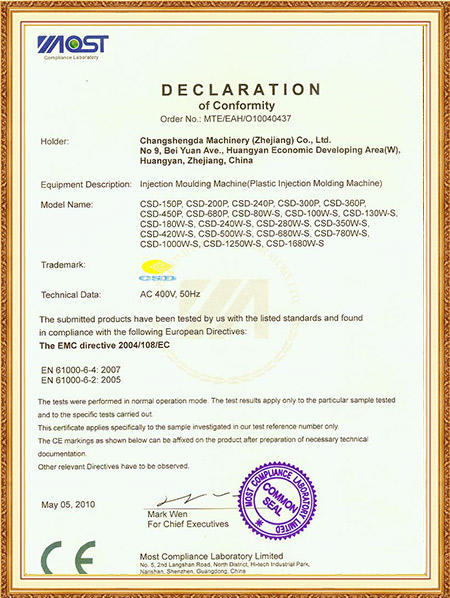

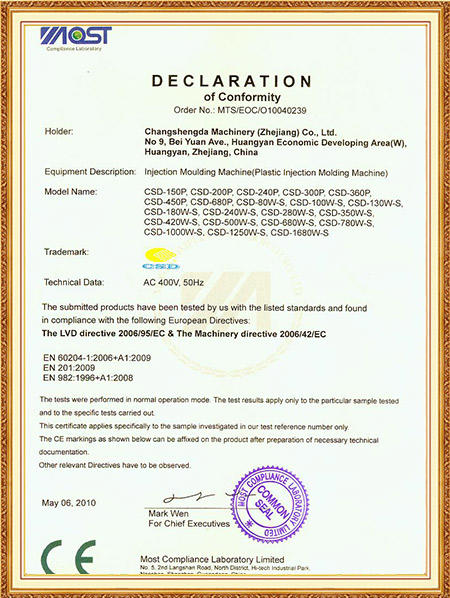

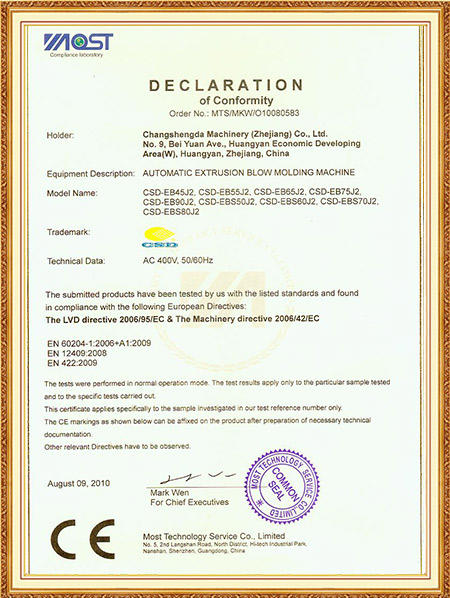

7. With European Community Safety Attestation TtUV CE certificate.

An automatic blow molding machine is a machine used to produce hollow plastic parts, such as bottles and containers, through a process called blow molding. The machine typically consists of a preform injection system, a blow mold, and a take-out system. The preform injection system injects molten plastic into a mold, which is then blown into the final shape using high-pressure air. The take-out system removes the finished product from the machine. Automatic Blow Molding Machine can produce a wide range of products with high precision and efficiency.

CSD-LP High Speed Automatic Blow Molding Machine

CSD-AB Automatic Blow Molding Machine(Up Blow)

CSD-AX1-2.5L CSD-AX1-2L CSD-AX3-1.5L CSD-AX4-1.5L Automatic Blow Molding Machine(Down Blow)

CSD-AX1-5L CSD-AX1-10L CSD-AX2-5L CSD-AX2-10L Automatic Blow Molding Machine(Down Blow)

CSD-AX1-W-5L CSD-AX2-W-5L Automatic Blow Molding Machine(Down Blow)

CSD-AX(2-4)-M-0.3L Automatic Blow Molding Machine(Down Blow)

CSD-AX1-5GAL Automatic Blow Molding Machine(Down Blow)

CSD-AX1-M-5GAL Automatic Blow Molding Machine(Down Blow)

CSD-AX1-M-2.5L Automatic Blow Molding Machine(Down Blow)

Reliable Wholesale Supplier Of Injection Molding Machine

Changshengda Machinery (Zhejiang) Co., Ltd. was established in 1992, a wholly-owned Australian enterprise with a registered capital of US$5.2 million.The plant covers an area of 72,000 square meters. As China Automatic Blow Molding Machine Manufacturers and Automatic Blow Molding Machine factory, we are specializes in the development and production of environmentally friendly, high-precision, medical and food injection molding machines, and PET automatic high-speed injection molding machines. In order to create a high-quality Changshengda brand and cast a first-class image of Changshengda, we continue to innovate products and implement the service promise of "turnkey project". We have set up many after-sales service agencies at home and abroad to provide new and old customers with high cost performance. Products and thorough after-sales service, our wholesale Automatic Blow Molding Machine were all exported and sold well in Southeast Asia, North and South America, Eastern Europe, Middle East, Europe, Africa and other countries and regions. Now it has successfully cooperated with dozens of domestic well-known brand enterprises. High efficiency and favored by domestic and foreign merchants.

News

-

Injection molding machine is also known as injection molding machine or injection machine. It is the main molding equipment for making thermoplastic or thermosetting plastics into various shapes of pl...

-

When the blow molding machine is working, the liquid plastic is sprayed out, and then the wind force blown by the machine is used to blow the plastic body to a certain shape of the mold cavity to make...

-

When the blow molding machine is working, the liquid plastic is sprayed out, and then the wind blowing from the machine is used to blow the plastic body to the mold cavity of a certain shape to make p...

-

Blow moulding machine is a machine that achieves cooling effect through steam compression or absorption cycle. These liquids can flow through heat exchangers to cool the air or equipment. Vapor-compre...

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语