Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

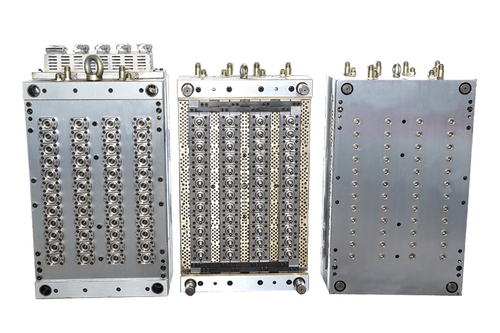

Preform mold Manufacturers

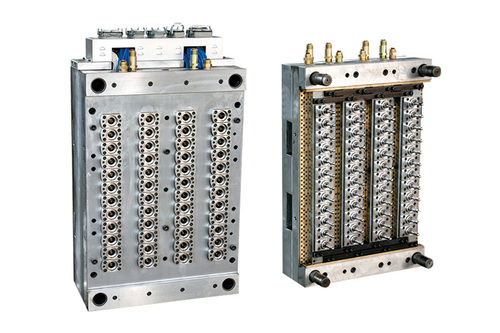

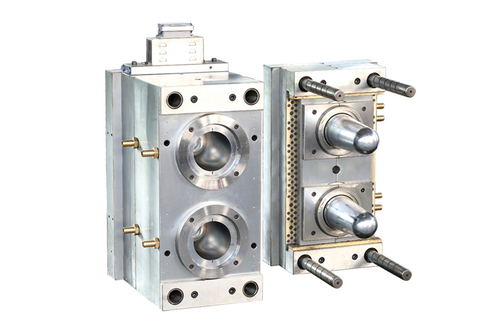

Two Weights Prefrom Hot Runner Sharing Mold

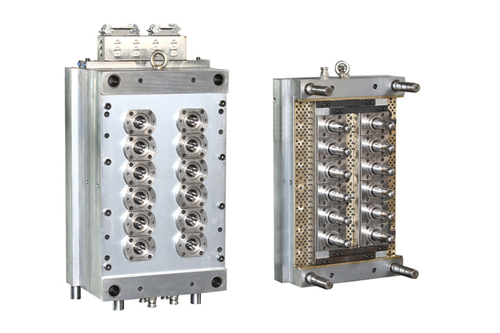

Preform Mold

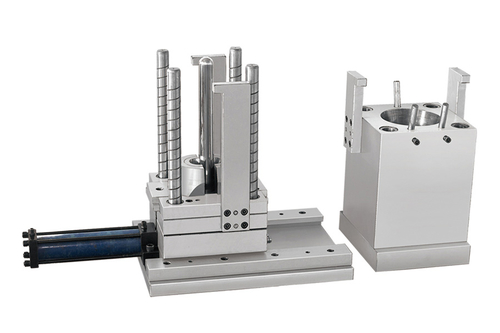

Preform Mold(45mm)

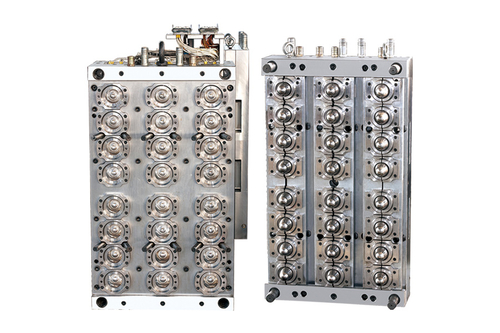

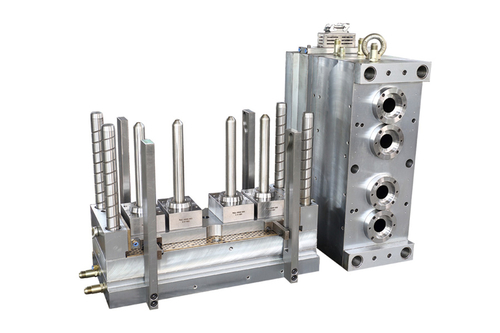

Jar Preform Mold

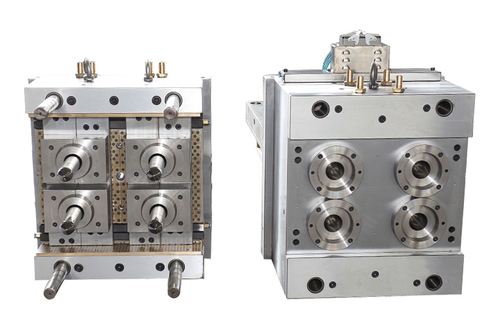

4 Cavity 3-Gallon Preform Mold

Jar Preform Mold

Jar Preform Mold

5 Gallon Preform Mold

5 Gallon Preform Mold

Reliable Wholesale Supplier Of Injection Molding Machine

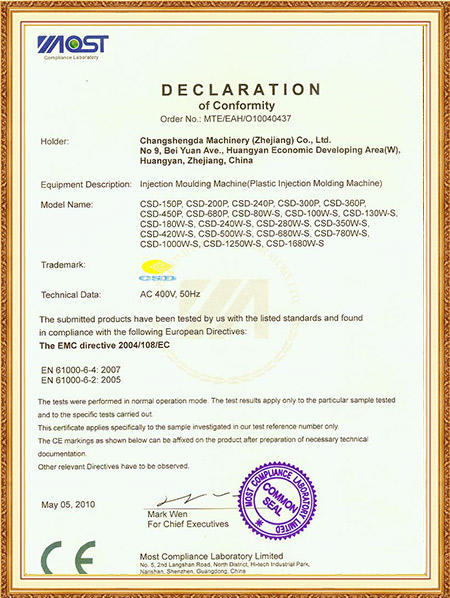

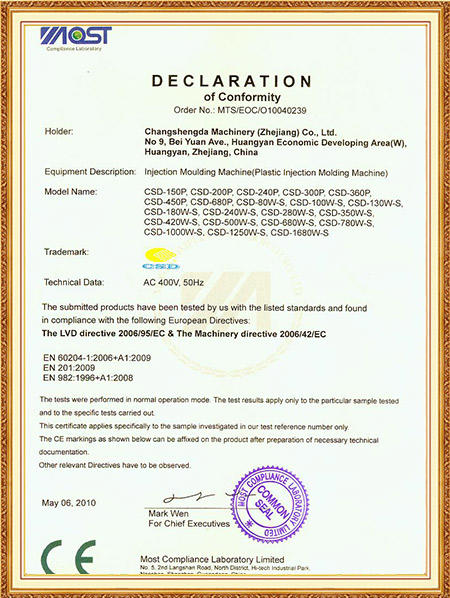

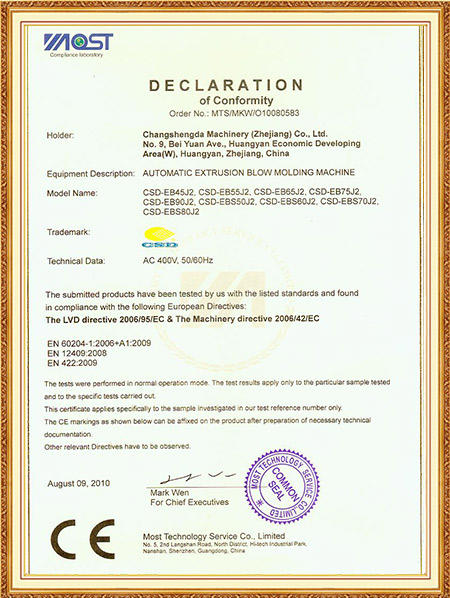

Changshengda Machinery (Zhejiang) Co., Ltd. was established in 1992, a wholly-owned Australian enterprise with a registered capital of US$5.2 million.The plant covers an area of 72,000 square meters. As China Preform mold Manufacturers and pet Preform mold suppliers, we are specializes in the development and production of environmentally friendly, high-precision, medical and food injection molding machines, and PET automatic high-speed injection molding machines. In order to create a high-quality Changshengda brand and cast a first-class image of Changshengda, we continue to innovate products and implement the service promise of "turnkey project". We have set up many after-sales service agencies at home and abroad to provide new and old customers with high cost performance. Products and thorough after-sales service, our custom pet Preform mold were all exported and sold well in Southeast Asia, North and South America, Eastern Europe, Middle East, Europe, Africa and other countries and regions. Now it has successfully cooperated with dozens of domestic well-known brand enterprises. High efficiency and favored by domestic and foreign merchants.

News

-

(1) Injection system Effect of injection system: Injection system is one of the most important components of Ningbo injection molding machine. Generally, there are three main methods: plunger type, sc...

-

In addition to the added injection moulding machine factory complexity of the mold structure, adding any of these features will significantly increase the cost of the mold (and the cost of the product...

-

1. The cost of blow moulding machine(especially blow molding molds) is lower (when molding similar products, the cost of blow molding machines is about 1/3-1/2 of that of injection molding machines), ...

-

The processing of blow mold products and toys requires the guarantee of resources to ensure smooth production. Two basic conditions complicate the management of resources. When multiple new projects a...

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语