Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

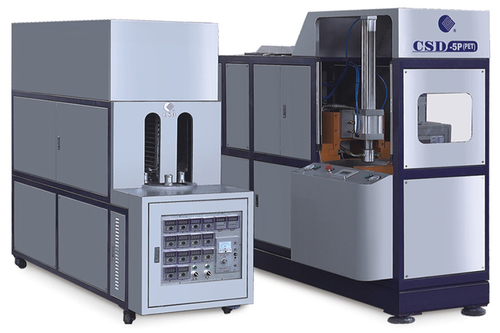

CSD-AX1-W-5L CSD-AX2-W-5L Automatic Blow Molding Machine

The blow molding machine is used in the cooling of plastic processing machinery forming molds, which can greatly improve the surface finish of plastic products, reduce the surface marks and internal stress of plastic products, make the products not shrink or deform, facilitate the demoulding of plastic products, and speed up product shaping. Thereby improving the production efficiency of the plastic molding machine.

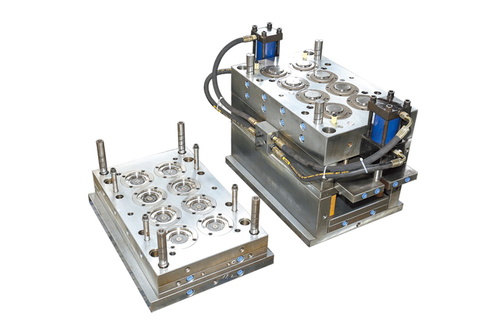

The mold function can accurately control the temperature required by modern industrial mechanized production, thereby greatly improving the production efficiency and product quality, and can also use the laboratory to achieve the desired temperature. It has the characteristics of controllable temperature, stable temperature and high condensation power.

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语