Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

Automatic Injection Molding Machine Manufacturers

Separate oil circular controlsupports synchronous mould open/close ejection function.Backproducts belt conveyor available forthe preform coolingand the connecting continuousautomatic production line.

An automatic injection molding machine is a type of industrial equipment used for manufacturing plastic parts and products by automatic injection molding machine into a mold. It typically consists of a hopper for holding the raw plastic material, a heating system for melting the material, a screw or ram injector for injecting the melted material into the mold, and a mold clamping mechanism for holding the mold closed during the injection process. The machine is controlled by a computer program, which allows for precise control of the injection process and the ability to produce high-quality, consistent parts.

CSD-P Pet Preform Series Injection Molding Machine

CSD-PET-DP High Speed Preform Production Line

CSD-PET-OP Outside Cooling Production Line

CSD-SP Direct Pressure Injection Molding Machine

CSD-S-FG Direct Pressure Injection Molding Machine(Applied In Medicine,Food)

CSD-W-S Injection Molding Machine

CSD-S Servo Motor Series Injection Molding Machine

Reliable Wholesale Supplier Of Injection Molding Machine

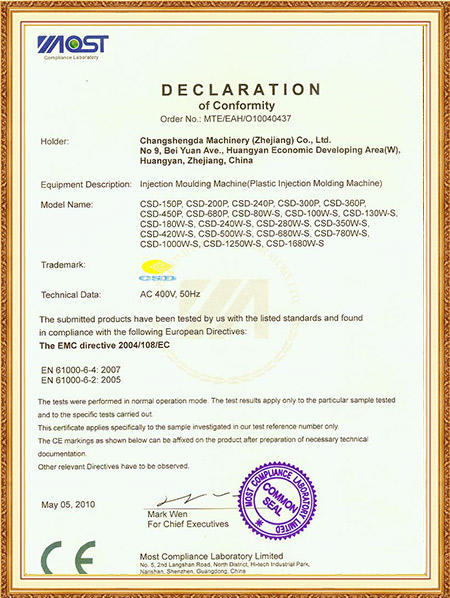

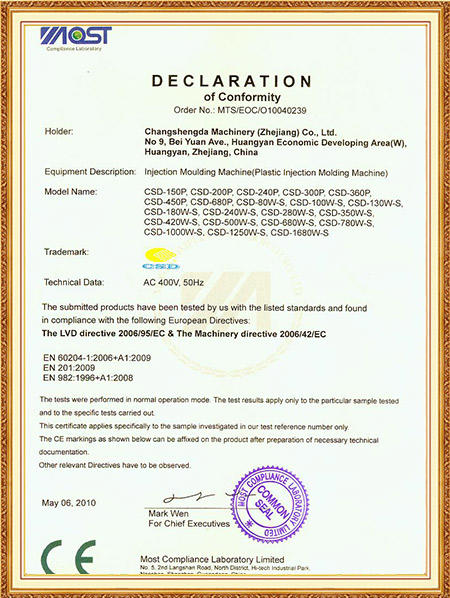

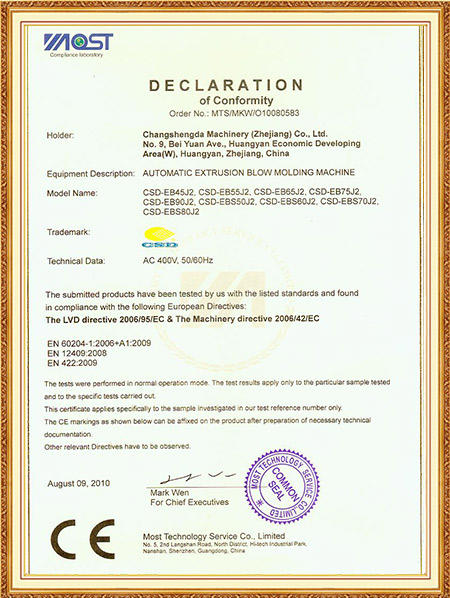

Changshengda Machinery (Zhejiang) Co., Ltd. was established in 1992, a wholly-owned Australian enterprise with a registered capital of US$5.2 million.The plant covers an area of 72,000 square meters. As China Automatic Injection Molding Machine Manufacturers and PET high-speed injection molding machines factory, we are specializes in the development and production of environmentally friendly, high-precision, medical and food injection molding machines, and PET automatic high-speed injection molding machines. In order to create a high-quality Changshengda brand and cast a first-class image of Changshengda, we continue to innovate products and implement the service promise of "turnkey project". We have set up many after-sales service agencies at home and abroad to provide new and old customers with high cost performance. Products and thorough after-sales service, our wholesale PET high-speed injection molding machines factory were all exported and sold well in Southeast Asia, North and South America, Eastern Europe, Middle East, Europe, Africa and other countries and regions. Now it has successfully cooperated with dozens of domestic well-known brand enterprises. High efficiency and favored by domestic and foreign merchants.

News

-

Permanent mold casting is a casting process that, as the name suggests, involves the use of a permanent mold. Unlike with casting processes, the mold can be reused for multiple casting applications. D...

-

Simple circular or cylindrical Vacuum forming or blow molding in female mold shapes. The thicker the sheet, the larger the bend diameter must be to prevent high stress concentrations. Ex: consumer pac...

-

Blow moulding machine is a manufacturing process used for the production of plastic bottles, containers, and custom shapes. This manufacturing process can be accomplished through different methods, bu...

-

The die portion of the blow mold should be a sharp cut to facilitate cutting the parison. The Z minimum longitudinal length of the jaw for cutting the parison is 0.5-2.5mm. If it is too small, it will...

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语