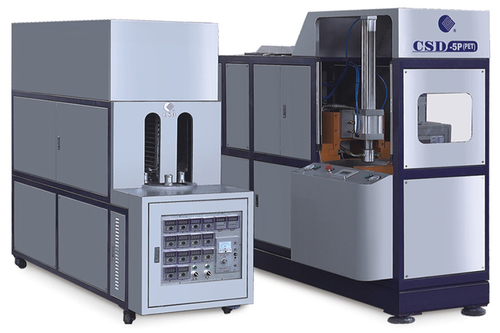

Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

In the dynamic realm of manufacturing technology, where precision and efficiency are paramount, the Direct Pressure Injection Molding Machine has emerged as a game-changer, revolutionizing the way products are crafted with unparalleled accuracy. This cutting-edge technology offers manufacturers the ability to create intricate and high-quality components, setting new standards in the world of injection molding. Let's explore the transformative impact of Direct Pressure Injection Molding Machines on the manufacturing landscape.

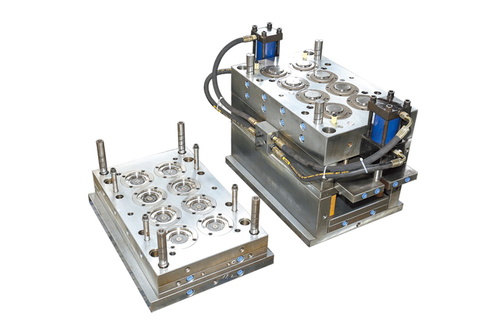

The defining feature of Direct Pressure Injection Molding Machines lies in their advanced injection molding process, which involves the direct application of pressure during the molding cycle. Unlike traditional injection molding machines, where pressure is applied indirectly through hydraulic systems, direct pressure injection molding ensures precise control over the injection process. This innovative approach allows manufacturers to achieve greater accuracy and consistency in the production of intricate parts and components.

One of the standout features of Direct Pressure Injection Molding Machines is their ability to optimize the entire injection molding cycle. The direct application of pressure streamlines the process, reducing cycle times and enhancing overall efficiency. Manufacturers benefit from increased productivity, enabling them to meet high-volume production demands without compromising on the quality of the molded products. This efficiency boost is particularly valuable in industries where rapid production turnaround is crucial.

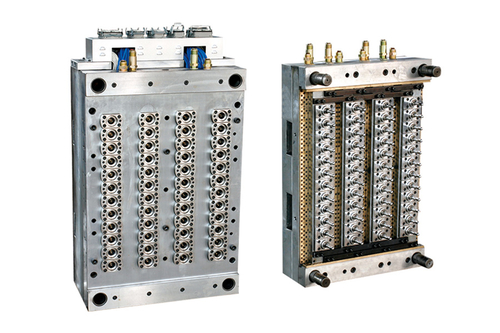

The precision achieved by Direct Pressure Injection Molding Machines is a result of the direct control over the injection process. The technology allows for accurate monitoring and adjustment of pressure levels, ensuring uniform filling of molds and minimizing defects in the final products. This level of precision is especially beneficial for the production of complex and intricate components used in various industries, including automotive, electronics, and medical devices.

In an era where quality and consistency are non-negotiable in manufacturing, Direct Pressure Injection Molding Machines set a new standard for excellence. The technology not only ensures the production of high-quality parts but also reduces the likelihood of defects and variations in the molded products. Manufacturers can confidently deliver components that meet stringent industry standards and customer expectations.

The versatility of Direct Pressure Injection Molding Machines extends to their applicability across a wide range of materials. Whether molding thermoplastics, thermosetting plastics, or elastomers, the technology accommodates diverse material requirements. This flexibility allows manufacturers to explore innovative materials and expand the scope of applications for injection-molded products.

Manufacturers investing in Direct Pressure Injection Molding Machines benefit from the integration of smart and automated features. Advanced models may include real-time monitoring systems, predictive maintenance capabilities, and intuitive controls for seamless operation. These features contribute to the overall efficiency of the manufacturing process, empowering operators with the tools needed to optimize production and minimize downtime.

The success stories from manufacturers adopting Direct Pressure Injection Molding Machines underscore their transformative impact on the industry. John Anderson, a production manager, shares, "The precision and efficiency of our production have significantly improved since we adopted direct pressure injection molding. We've seen a reduction in defects, faster cycle times, and overall improved product quality."

As we navigate the evolving landscape of manufacturing technology, Direct Pressure Injection Molding Machines emerge as a symbol of innovation and efficiency. In a world where precision and speed are essential for meeting market demands, this technology sets the stage for a new era of injection molding. It's not just a machine; it's a catalyst for elevating manufacturing processes to unprecedented levels of accuracy and efficiency. The transformative power of Direct Pressure Injection Molding Machines is reshaping the future of injection molding, offering manufacturers a pathway to excellence in the production of intricate and high-quality components.

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语