Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

In the realm of precision manufacturing, one technology stands out as a game-changer: the Direct Pressure Injection Molding Machine. This innovative apparatus, often referred to simply as the DPI Molding Machine, has revolutionized the production of intricate and high-quality plastic parts across various industries. By employing advanced techniques and state-of-the-art engineering, the DPI Molding Machine has become an indispensable tool for manufacturers looking to enhance their productivity and product quality.

The Direct Pressure Injection Molding Machine, abbreviated as DPI, is at the forefront of modern manufacturing processes. This marvel of engineering combines cutting-edge technology and precision to produce intricate plastic components with unparalleled accuracy and efficiency. This article will delve into the workings of the DPI Molding Machine, its applications, and its significant impact on the manufacturing landscape.

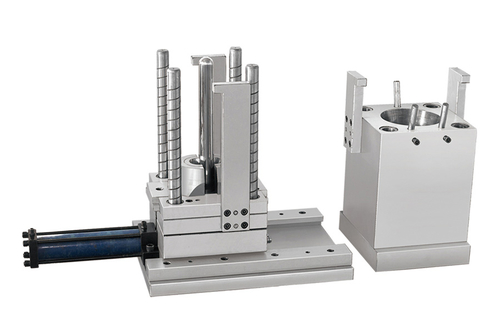

The Direct Pressure Injection Molding Machine is a complex apparatus that excels in transforming raw plastic materials into finely crafted products. This machine boasts a versatile design, allowing it to be employed in diverse industries, from automotive and electronics to medical devices and consumer goods.

At its core, the DPI Molding Machine operates on the principle of injecting molten plastic material into a meticulously crafted mold, ensuring consistent quality and precise dimensions. This process is conducted under intense pressure, which minimizes defects and guarantees the integrity of the final product.

The DPI Molding Machine uses a hydraulic system to generate the required pressure for molding. This hydraulic system is equipped with advanced controls, allowing operators to fine-tune the pressure and injection speed with pinpoint accuracy. This level of control is crucial for producing parts with complex geometries and tight tolerances.

One of the distinguishing features of the DPI Molding Machine is its direct pressure injection mechanism. Unlike traditional injection molding machines, which rely on indirect pressure, the DPI Machine applies pressure directly to the mold cavity. This results in superior part quality, reduced cycle times, and improved efficiency.

The Direct Pressure Injection Molding Machine's versatility knows no bounds. In the automotive sector, it plays a pivotal role in crafting precision components such as interior trim, sensors, and engine parts. Its ability to produce parts with exceptional dimensional stability makes it an ideal choice for this demanding industry.

The electronics industry also benefits significantly from the DPI Molding Machine. It can manufacture intricate components like connectors, housings, and circuit board enclosures with unparalleled precision, ensuring optimal functionality and reliability.

The medical field relies on the DPI Machine for producing sterile and accurate components for medical devices, such as syringe barrels and inhaler components. The direct pressure injection process minimizes the risk of contamination and ensures patient safety.

One of the key advantages of the Direct Pressure Injection Molding Machine is its ability to minimize material waste. The precision of the injection process means less material is required to produce each part, reducing costs and environmental impact.

Moreover, the DPI Machine's efficiency extends to its energy consumption. Advanced energy-saving features ensure that it operates with minimal power consumption, aligning with the global push for sustainable manufacturing practices.

In the world of precision manufacturing, the Direct Pressure Injection Molding Machine reigns supreme. Its advanced technology, direct pressure injection mechanism, and versatility have made it an indispensable tool for producing high-quality plastic parts in various industries. With its potential to reduce waste, improve efficiency, and contribute to sustainability, the DPI Machine has indeed reshaped the manufacturing landscape. As industries continue to evolve, it's clear that the Direct Pressure Injection Molding Machine will remain a cornerstone of modern manufacturing processes.

CSD-S-FG Direct Pressure Injection Molding Machine(Applied In Medicine,Food)

CSD-S-FG Direct Pressure Injection Molding Machine(Applied In Medicine,Food)

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语