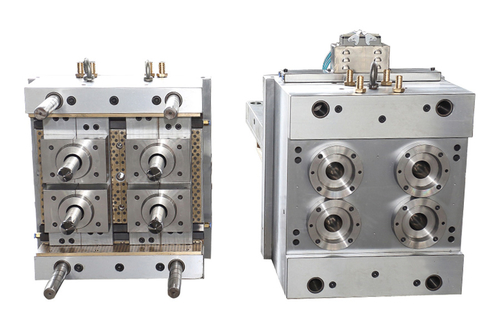

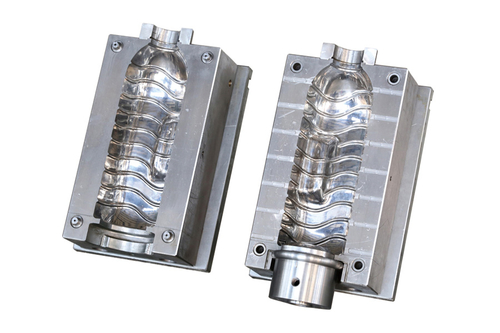

Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

Four reasons for uneven shrinkage:

1. The different melting temperature : the injection moulding machine high melting temperature will lead to larger shrinkage.

2. Different cooling rates (crystalline materials):

The shrinkage rate of the quick melt cooling is smaller than that of the slow melt cooling (Cause: The molecules with slow cooling rate have more time to cool down, so its amount of shrinkage is large)

3. The different flow direction of the melted (amorphous material): in short, the tensile internal force is large along the flow direction, so the amount of shrinkage is large.

During the filling process, the plastics cause alignment of the molecular chains due to the flow alignment.

The polymer chains to be aligned are subjected to different stretching conditions in the flow direction and the vertical flow direction, and the shrinkage behavior is also different. It is called directional shrinkage.

In general, the flow direction shrinkage rate is higher than the vertical flow shrinkage rate.

This is because the flow direction of the plastic polymer chain is stretched more seriously, and the trend of restoring the unstretched state is greater.

The differential shrinkage caused by the flow alignment often causes warpage of the plastic part.

Therefore, if the molecular alignment can be broken, it will contribute to the uniformity of shrinkage and reduce the warpage caused by the direction shrinkage.

4. Different sizes:the bigger size part will have larger shrinkage.

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语