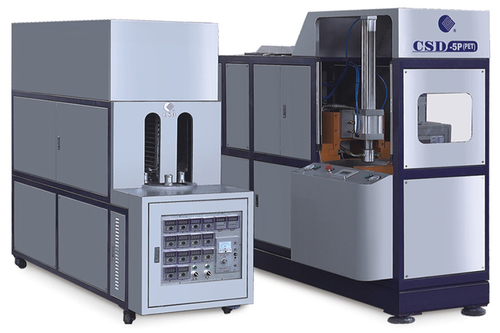

Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

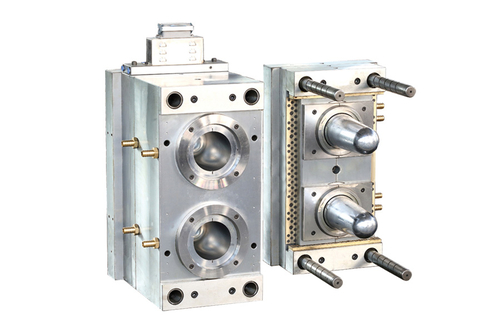

A plastic mold is a tool or device that is used to shape plastic materials into specific forms and sizes. It is a key component in the manufacturing process of many plastic products, such as toys, containers, electronic parts, automotive parts, and household items.

The plastic mold is typically made from a hard, durable material such as steel or aluminum, and it is designed with a cavity or cavities that are shaped to create the desired product. The mold is then placed into a molding machine that melts the plastic material and injects it into the mold. The plastic is then cooled and solidified to form the final product.

The use of plastic molds in the manufacturing process has several advantages. It allows for a high degree of precision and consistency in the shaping and sizing of plastic products, which can help to ensure that they meet strict quality standards. It also enables mass production of products at a fast rate and with a high level of efficiency, which can help to reduce production costs.

Overall, plastic molds are an essential tool in the manufacturing of plastic products, and their use has revolutionized the way that many consumer goods are produced.

12 Cavity Hot Runner Fork Mold

A 12 cavity hot runner fork mold is a tool used in the manufacturing process of plastic forks. The mold is designed to produce 12 forks at a time and is equipped with a hot runner system, which is used to heat and control the flow of plastic into the mold cavities.

The hot runner system consists of a series of heated channels that are located within the mold. These channels help to maintain a consistent temperature and pressure throughout the mold, which helps to ensure that each fork is of high quality and meets the desired specifications.

When the mold is in use, plastic is injected into the hot runner system and flows into each of the 12 cavities. Once the plastic has cooled and solidified, the mold is opened and the finished forks are removed.

A 12 cavity hot runner fork mold is typically used in high-volume production environments, such as in the manufacturing of plastic utensils for commercial use. The use of a hot runner system can help to increase production efficiency and reduce waste, making it a popular choice for manufacturers looking to streamline their production processes.

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语