Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

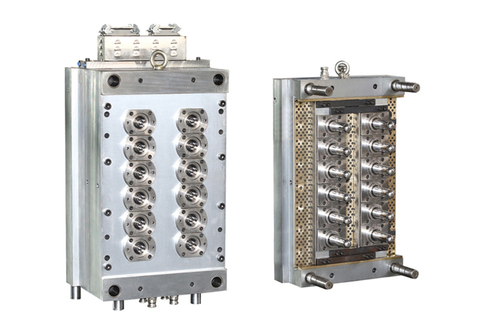

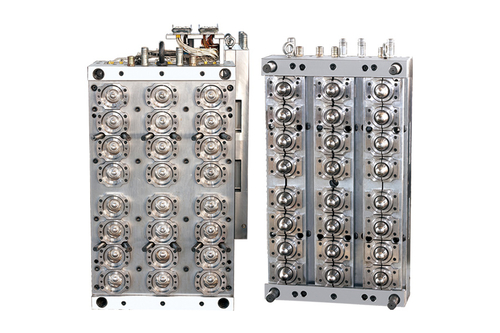

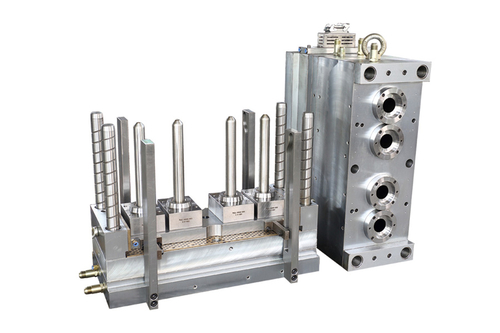

72 Cavity Hot Runner Medical Products Mold

That is to install the cast aluminum heating plate on the outside of the mold and heat it from the outside to the inside. This method heats up quickly, but consumes a lot of heat energy. It is more suitable for the cold winter in the north. For plastic bottle cap molds, the temperature can be raised by the heat of the injection material. The use of raw materials that are not difficult to inject does not require mold preheating.

However, for large and medium-sized molds, the molten material is forcibly injected into the mold cavity by using high-temperature materials and high pressure. Although it is possible to obtain parts for trial molds, the damage to the mold itself is actually serious, and energy is wasted. Due to the large internal stress and serious deformation of the obtained workpiece, its size is very unstable, which brings trouble to the inspection of the size of the workpiece.

Therefore, this method should not be used. While the mold is being preheated after installation, the injection barrel is also being heated. When both temperatures meet the requirements, that is, when the mold temperature reaches 30-60°C or above. When the plastic in the barrel is in a molten state and plasticized evenly, the temperature is considered appropriate, that is, the injection conditions for the trial mold are met, and the trial mold can enter the stage of trial injection.

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语