Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

The automatic injection molding machine stands at the forefront of modern manufacturing, heralding a new era of precision, speed, and efficiency. This remarkable machine combines cutting-edge technology with advanced engineering to transform raw materials into intricately designed plastic products. In this captivating description, we will delve into the innovative features and transformative capabilities of the automatic injection molding machine, showcasing its impact on various industries and its ability to revolutionize the manufacturing landscape.

The automatic injection molding machine redefines efficiency in manufacturing processes. Its advanced automation systems streamline production, reducing labor-intensive tasks and optimizing cycle times. With computer-controlled operations, the machine ensures consistent and accurate results, eliminating human error and enhancing overall productivity. The precise control over parameters such as temperature, pressure, and injection speed guarantees the production of high-quality plastic components with intricate details and minimal defects. The integration of robotic arms or conveyors further enhances efficiency, facilitating seamless material handling and part ejection. With faster cycle times and reduced downtime for tooling changes, the machine maximizes output and minimizes production costs, making it an invaluable asset for industries striving for high-volume and cost-effective manufacturing.

At the heart of the automatic injection molding machine lies its ability to deliver unrivaled precision. The machine employs state-of-the-art technology to monitor and regulate every aspect of the molding process. High-resolution sensors ensure precise control over temperature and pressure, optimizing the viscosity of the molten plastic for flawless molding. The injection unit, driven by servo motors, provides accurate shot sizes and injection speeds, allowing for intricate and detailed designs. The precise movement and positioning of the mold and platen, controlled by computer algorithms, ensure consistent and repeatable results. This level of precision translates into the production of components with tight tolerances and intricate geometries, meeting the stringent requirements of various industries, including automotive, electronics, and medical.

The automatic injection molding machine offers remarkable versatility and adaptability to cater to a wide range of manufacturing needs. Its modular design allows for easy customization and integration of additional components, such as auxiliary equipment or specialized injection units, to accommodate different materials or processes. The machine is compatible with a variety of thermoplastics, enabling the production of components with diverse properties, ranging from flexible to rigid. Moreover, it supports multi-cavity molds, allowing for simultaneous production of multiple parts in a single cycle. The flexibility to switch between molds and materials quickly makes it suitable for small-batch production or just-in-time manufacturing. The automatic injection molding machine empowers manufacturers with the agility to respond to market demands promptly while maintaining exceptional quality and efficiency.

The automatic injection molding machine has become a game-changer in the manufacturing landscape, revolutionizing the way plastic components are produced. With its unrivaled efficiency, precision engineering, and versatility, it has raised the bar for productivity and quality. Embrace the power of automation and experience the transformative capabilities of the automatic injection molding machine as it reshapes manufacturing processes and drives innovation forward.

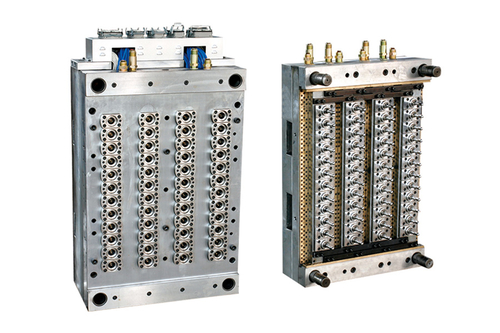

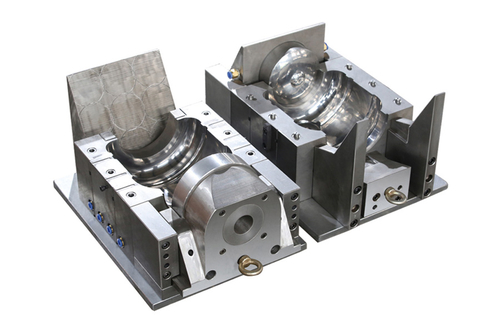

CSD-SP Direct Pressure Injection Molding Machine

CSD-SP Direct Pressure Injection Molding Machine

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语