Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

The Extrusion Blow Molding Machine stands as a pinnacle of manufacturing precision, seamlessly combining art and science to create a wide array of hollow plastic products. This specialized machine has transformed the landscape of plastic manufacturing, setting unparalleled standards of quality and efficiency. In this comprehensive exploration, we delve into the world of the Extrusion Blow Molding Machine, unraveling its design, advantages, and the transformative impact it has had on the production of hollow plastic products.

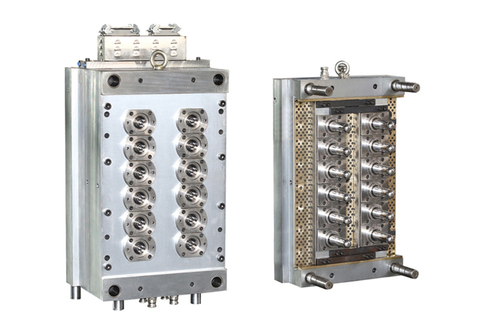

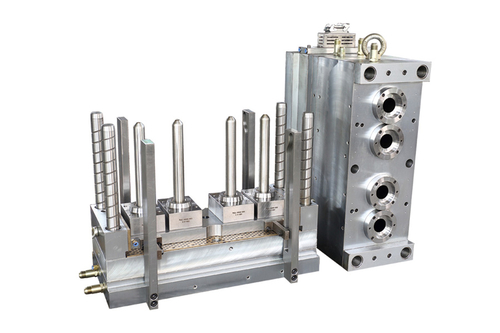

The Extrusion Blow Molding Machine is meticulously engineered to deliver superior performance and precision in the manufacturing of hollow plastic products. Its design revolves around the extrusion blow molding process, where a heated plastic material is extruded and shaped to form hollow containers. This machine has become a cornerstone in the manufacturing of bottles, containers, and various plastic products.

One of the primary advantages of the Extrusion Blow Molding Machine is its versatility. This machine can produce a wide variety of hollow plastic products, ranging from simple bottles to complex containers with intricate designs. The flexibility of the extrusion blow molding process allows for the creation of customized products to meet specific industry and consumer demands.

Moreover, the Extrusion Blow Molding Machine offers efficiency and speed in the manufacturing process. The continuous extrusion process enables faster production cycles, resulting in higher output and meeting high production demands. The machine's automation ensures a streamlined and continuous manufacturing process, optimizing productivity and reducing operational costs.

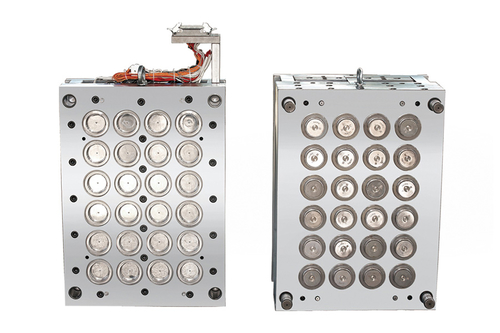

In the realm of manufacturing and production, the Extrusion Blow Molding Machine has emerged as an indispensable tool. Its versatility in creating a diverse range of hollow plastic products positions it as a preferred choice for various industries, including packaging, automotive, consumer goods, and more. The extrusion blow molding process allows for the efficient production of consistent and high-quality products.

Furthermore, the automation in the Extrusion Blow Molding Machine significantly reduces labor requirements and enhances safety. The automated processes, from material feeding to molding and product ejection, minimize manual intervention and improve overall workplace safety. This automation not only enhances efficiency but also reduces operational costs, making it a cost-effective solution for manufacturers.

In the world of hollow plastic product manufacturing, the Extrusion Blow Molding Machine stands as a symbol of innovation and efficiency. Its specialization in the extrusion blow molding process has not only optimized manufacturing but has also paved the way for advancements in product design and functionality. The machine's ability to produce diverse hollow plastic products with precision and speed has made it a cornerstone in modern manufacturing.

The ongoing innovation and development in the Extrusion Blow Molding Machine sector are driven by the need to enhance efficiency, reduce energy consumption, and minimize environmental impact. Modern variations may include advancements in material usage, energy-saving features, and improved automation for an even more streamlined manufacturing process.

In conclusion, the Extrusion Blow Molding Machine is a transformative force in hollow plastic product manufacturing. Its specialization in the extrusion blow molding process, combined with automation and versatility, has revolutionized the industry. As industries continue to evolve and demand more efficient and precise manufacturing solutions, the Extrusion Blow Molding Machine remains at the forefront, shaping the future of hollow plastic product manufacturing and meeting the needs of modern production.

CSD-EB45J2 Extrusion Blow Molding Machine

CSD-EB45J2 Extrusion Blow Molding Machine

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语