Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

1.Design: The first step in designing a preform mold is to create a 3D model of the part or product that will be made from the mold. This can be done using CAD (Computer-Aided Design) software, which allows the designer to create a detailed and accurate digital model of the part.

2.Mold Base: Once the design is complete, the mold base is created. The mold base is the foundation of the mold and provides a platform for the other components to be attached. Typically, the mold base is made of steel or aluminum and is machined to the required specifications.

3.Core and Cavity: The next step is to create the core and cavity components of the mold. These components are responsible for forming the preform. The cavity is the negative space where the preform will be formed, and the core is the positive space that creates the preform's shape. Typically, the core and cavity are made of hardened steel and are manufactured using CNC (Computer Numerical Control) machines.

4.Cooling System: A cooling system is essential to control the temperature of the mold during the manufacturing process. The cooling system consists of channels that run through the mold and are filled with cooling fluid, typically water. The cooling system helps to control the temperature of the mold, which is critical in ensuring consistent and high-quality preform production.

5.Assembly and Testing: Once all of the components are manufactured, they are assembled and tested. The mold components are put together, and the mold is tested to ensure that it produces the preform as designed. Adjustments are made as needed to optimize the mold's performance.

Overall, designing and manufacturing preform molds is a complex process that requires expertise in various fields such as engineering, manufacturing, and material science. The process requires precision, accuracy, and attention to detail to produce high-quality preforms.

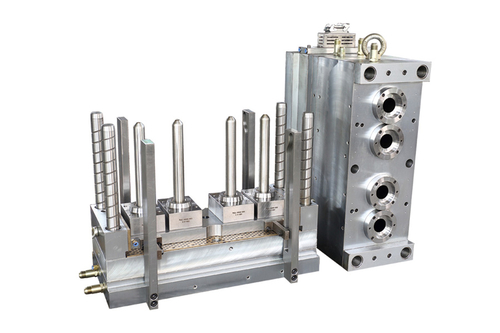

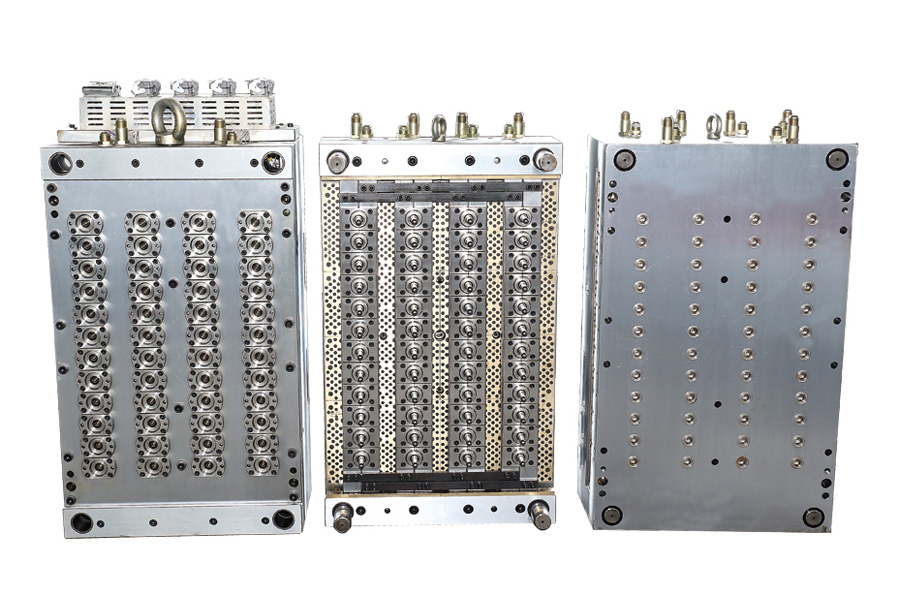

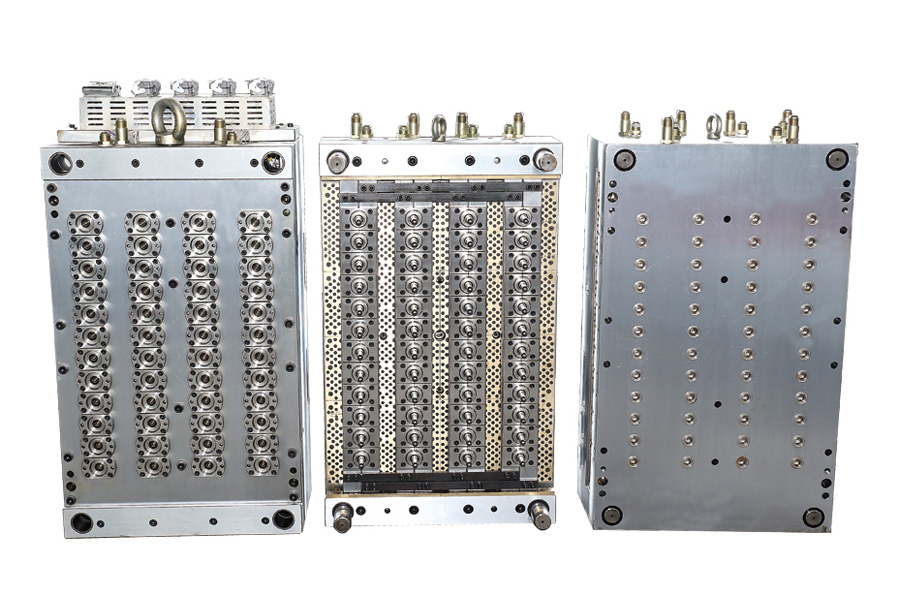

Two Weights Prefrom Hot Runner Sharing Mold

Two Weights Prefrom Hot Runner Sharing Mold

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语