Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

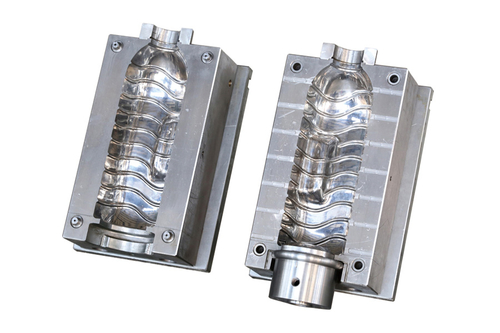

In the fast-paced world of manufacturing, where efficiency and speed are paramount, the High Speed Automatic Blow Molding Machine has emerged as a technological marvel, reshaping the landscape of container production. This cutting-edge machine stands at the forefront of innovation, offering manufacturers an unparalleled combination of precision and rapid production capabilities. Let's delve into the groundbreaking features of the High Speed Automatic Blow Molding Machine and its transformative impact on the manufacturing industry.

The defining feature of the High Speed Automatic Blow Molding Machine lies in its ability to operate at remarkable speeds, significantly reducing cycle times and increasing overall production efficiency. Unlike conventional blow molding machines, the high-speed variant leverages advanced technology to optimize the molding process, enabling manufacturers to meet the demands of high-volume production without compromising on quality.

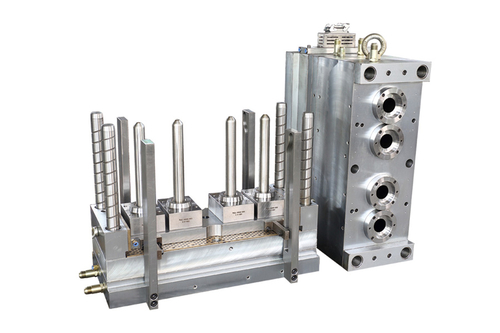

One of the standout features of this automatic blow molding machine is its exceptional production speed. The advanced mechanisms and optimized processes allow for rapid mold closing, blowing, and ejection cycles. This efficiency boost translates into a higher number of containers produced per unit of time, making the High Speed Automatic Blow Molding Machine an invaluable asset for industries where large-scale container production is a constant demand.

The precision achieved by the High Speed Automatic Blow Molding Machine is a testament to its sophisticated engineering. The machine is equipped with precise control systems that monitor and adjust various parameters during the molding process. This level of precision ensures uniform thickness, consistent quality, and dimensional accuracy in the containers being produced. Manufacturers can confidently deliver containers that meet stringent industry standards, even at the high speeds maintained by the machine.

In an era where manufacturers are under constant pressure to enhance production efficiency, the High Speed Automatic Blow Molding Machine sets a new standard for excellence. The technology not only optimizes the production process but also reduces the likelihood of defects and variations in the final products. This is particularly crucial in industries such as packaging, where container quality is directly linked to product safety and shelf appeal.

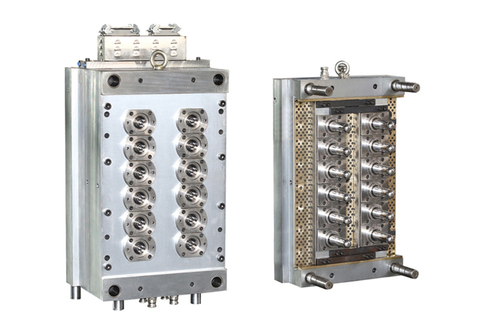

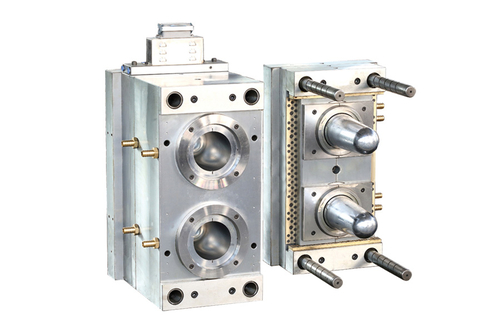

The versatility of the High Speed Automatic Blow Molding Machine extends to its applicability across a wide range of container sizes and shapes. Whether producing small bottles, large containers, or custom designs, the machine accommodates diverse production requirements. This adaptability allows manufacturers to navigate the evolving demands of the market and respond to changing consumer preferences with agility.

Manufacturers investing in the High Speed Automatic Blow Molding Machine benefit from the integration of smart and automated features. Advanced models may include real-time monitoring systems, predictive maintenance capabilities, and user-friendly controls for seamless operation. These features contribute to the overall efficiency of the container production process, empowering operators with the tools needed to optimize production and minimize downtime.

The success stories from manufacturers adopting the High Speed Automatic Blow Molding Machine underscore its transformative impact on the industry. David Thompson, a production manager, shares, "Our production capacity has seen a significant increase since we adopted the high-speed blow molding machine. The combination of speed and precision has allowed us to stay ahead in a competitive market."

As we navigate the ever-evolving landscape of manufacturing technology, the High Speed Automatic Blow Molding Machine emerges as a symbol of innovation and efficiency. In a world where time is of the essence, this technology sets the stage for a new era of high-speed container production. It's not just a machine; it's a catalyst for elevating manufacturing processes to unprecedented levels of speed and precision. The transformative power of the High Speed Automatic Blow Molding Machine is reshaping the future of container manufacturing, offering manufacturers a pathway to excellence in the rapid and precise production of containers to meet the demands of modern industry.

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语