Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

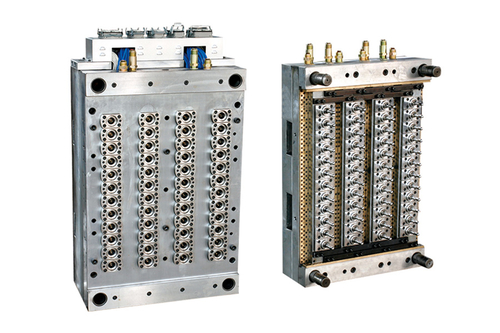

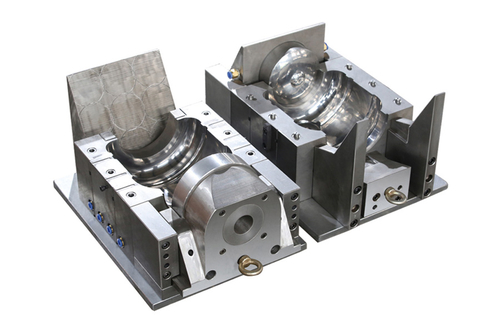

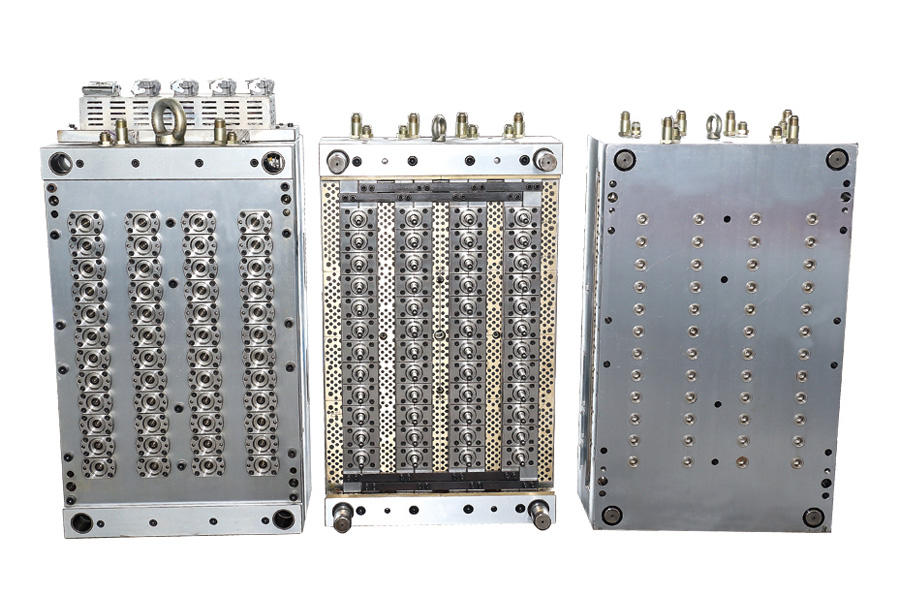

The concept of two weights preform hot runner sharing mold revolutionizes the production of PET (Polyethylene Terephthalate) preforms for the beverage industry. By utilizing a single mold to produce preforms of different weights, this innovative approach offers numerous advantages in terms of efficiency, cost-effectiveness, and flexibility. In this descriptive piece, we will delve into the features and benefits of the two weights preform hot runner sharing mold, showcasing its impact on the manufacturing process and the benefits it brings to preform producers.

The two weights preform hot runner sharing mold optimizes efficiency and cost-effectiveness in preform production. By using a single mold, manufacturers can produce preforms of different weights, eliminating the need for separate molds for each weight variant. This reduces tooling costs, simplifies mold changeovers, and minimizes production downtime. The shared hot runner system enables precise control over material flow, ensuring consistent preform quality and reducing material waste. Additionally, the reduced number of molds and changeovers streamline the production process, increasing overall throughput and productivity.

The two weights preform hot runner sharing mold offers exceptional flexibility and adaptability in preform manufacturing. With this mold, producers can easily switch between different preform weights by adjusting the mold cavity configurations. This versatility allows manufacturers to quickly respond to market demands and adapt to changing customer preferences without investing in additional molds. The mold's design accommodates a wide range of preform weights, providing flexibility to produce a variety of bottle sizes and shapes. The ability to produce different preform weights using the same mold also reduces inventory and storage requirements, further enhancing operational efficiency.

The two weights preform hot runner sharing mold ensures consistent preform quality throughout the production process. The shared hot runner system maintains precise temperature control, enabling uniform material distribution and consistent wall thickness across different preform weights. The optimized material flow and cooling system minimize defects, such as color variations, crystallization, or stress marks. The result is a batch of preforms with consistent physical properties, dimensions, and appearance, meeting the stringent quality standards of the beverage industry. Consistency in preform quality reduces the rejection rate, enhances bottle production efficiency, and improves overall customer satisfaction.

The two weights preform hot runner sharing mold represents a significant advancement in the production of PET preforms. With its focus on efficiency, cost-effectiveness, and flexibility, it offers manufacturers a competitive edge in the beverage industry. Embrace the benefits of reduced tooling costs, increased productivity, and consistent preform quality as you explore the potential of this innovative mold. Experience the transformative power of the two weights preform hot runner sharing mold and elevate your preform production to new heights of efficiency and excellence.

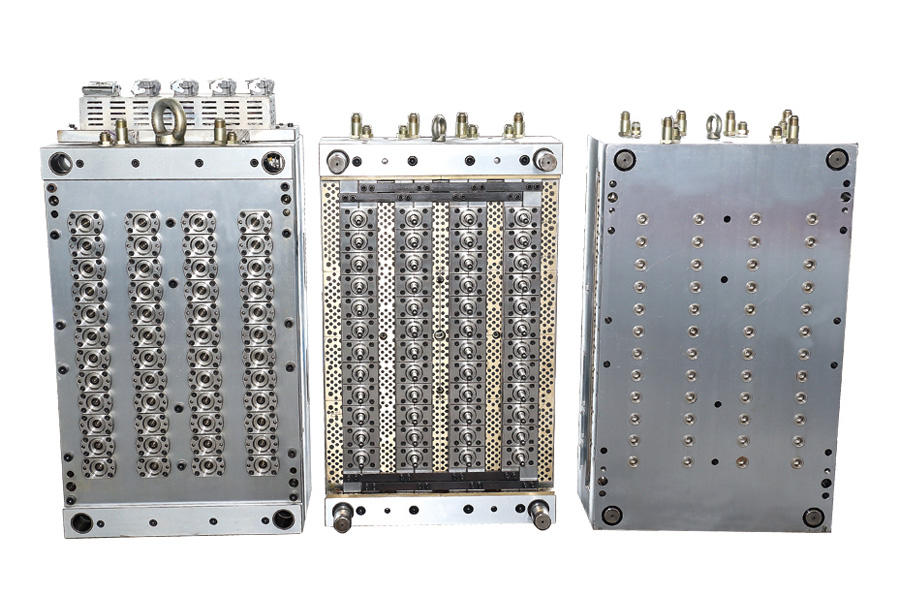

Two Weights Prefrom Hot Runner Sharing Mold

Two Weights Prefrom Hot Runner Sharing Mold

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语