Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

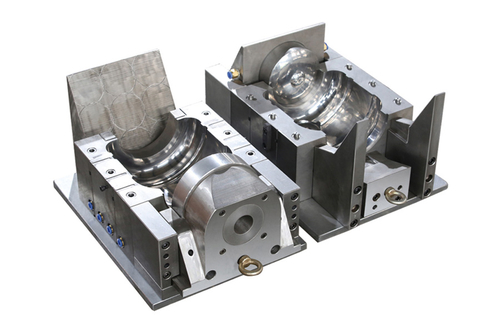

In the realm of plastic container production, the CSD-2P Semi-Automatic Blow Molding Machine emerges as a versatile and efficient solution, blending automated features with manual operation to streamline the manufacturing process. This specialized machine stands as a testament to innovation and adaptability, catering to various industries reliant on plastic container solutions.

At its core, the CSD-2P Semi-Automatic Blow Molding Machine represents a harmonious fusion of advanced technology and user-friendly design, specifically tailored for the production of plastic containers. This machine offers a unique balance between automation and manual intervention, providing manufacturers with a flexible and efficient production solution.

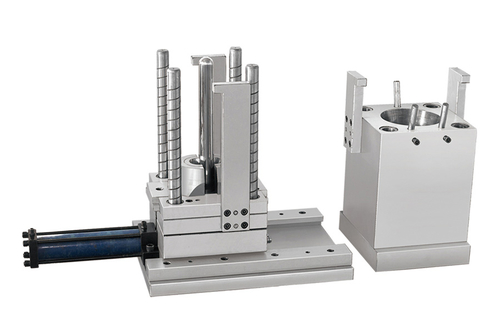

The standout feature of this blow molding machine lies in its semi-automated functionality. The CSD-2P series combines automated processes, such as preform heating and stretching, with manual operations for mold clamping, blowing, and ejection, allowing operators to have more control and precision over the manufacturing process.

Functionality is a defining aspect of the CSD-2P Semi-Automatic Blow Molding Machine. Its user-friendly interface and intuitive controls empower operators to oversee critical aspects of the production process, ensuring consistent and high-quality output while allowing flexibility for adjustments based on specific container requirements.

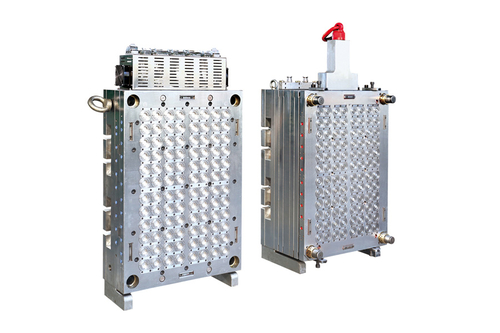

Moreover, the versatility of this machine extends to its adaptability for various container sizes and shapes. The CSD-2P series accommodates different preform designs, enabling manufacturers to produce a wide range of containers, from small-sized bottles to larger containers, addressing diverse packaging needs.

The machine's semi-automated operation also contributes to increased productivity and reduced manufacturing times. While offering manual control for critical steps, its semi-automated features streamline the production process, enhancing efficiency without compromising on quality.

In conclusion, the CSD-2P Semi-Automatic Blow Molding Machine represents a paradigm shift in container manufacturing, offering a unique blend of automation and manual operation. Its semi-automated functionality, versatility, and efficiency cater to the evolving needs of industries relying on plastic containers.

As the demand for customizable and efficiently produced plastic containers continues to rise across various sectors such as beverages, cosmetics, and household products, the CSD-2P Semi-Automatic Blow Molding Machine stands as a versatile tool, contributing to the efficiency, quality, and competitiveness of manufacturers in the packaging industry.

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语