Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

In the realm of packaging manufacturing, jar PET preform moulds are essential components that enable the production of high-quality and durable containers for a variety of products. These specialized molds, designed to shape PET (polyethylene terephthalate) plastic into preform blanks for jars, play a crucial role in ensuring the efficiency, precision, and reliability of the packaging process. With their advanced features and innovative designs, jar PET preform moulds are revolutionizing the way companies produce and distribute their products, driving excellence and innovation in the packaging industry.

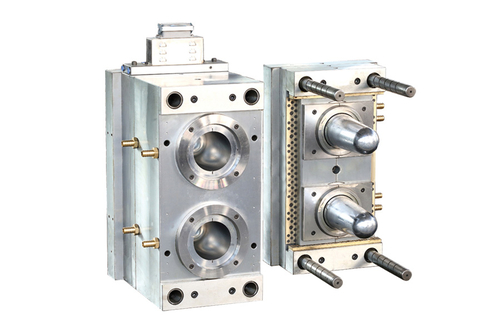

Jar PET preform moulds are engineered to exacting standards to meet the stringent requirements of the packaging industry. Leveraging state-of-the-art design software and precision machining technologies, mold manufacturers meticulously craft each mold with intricate cavity designs, precise dimensions, and smooth surface finishes. This precision is essential for producing preform blanks that meet the specifications of companies in industries such as food and beverage, personal care, and household products, where packaging plays a critical role in product safety, preservation, and branding.

Moreover, jar PET preform moulds offer versatility and flexibility in design to accommodate the diverse needs and preferences of packaging manufacturers. Whether producing molds for standard jar sizes or creating custom molds for unique shapes and designs, mold manufacturers work closely with their clients to develop molds that align with their product requirements, branding objectives, and production processes. Additionally, jar PET preform moulds can be equipped with features such as multi-cavity configurations, interchangeable inserts, and hot runner systems to enhance productivity, efficiency, and cost-effectiveness in mold production and usage.

In addition to their precision and versatility, jar PET preform moulds contribute to sustainability and environmental responsibility in the packaging industry. By optimizing mold designs for material efficiency, minimizing waste in the manufacturing process, and promoting the use of recycled and recyclable materials, mold manufacturers help their clients reduce their environmental footprint and minimize packaging waste. Additionally, jar PET preform moulds enable companies to produce lightweight and durable packaging solutions that enhance product shelf life, reduce transportation costs, and minimize the use of secondary packaging materials.

Furthermore, jar PET preform moulds play a crucial role in driving innovation and advancement in the packaging industry. Through ongoing research and development initiatives, mold manufacturers continuously explore new materials, technologies, and manufacturing techniques to improve mold performance, efficiency, and durability. By staying at the forefront of technological advancements and industry trends, jar PET preform mould manufacturers enable their clients to remain competitive and successful in a rapidly evolving marketplace, driving excellence and innovation in packaging design and production.

Another important aspect of jar PET preform moulds is their impact on product quality and consumer satisfaction. By producing preform blanks with consistent dimensions, wall thicknesses, and surface finishes, these molds ensure that jars produced from these preforms meet the highest standards of quality and performance. This reliability is essential for enhancing brand reputation, building consumer trust, and driving repeat purchases, as consumers associate high-quality packaging with product freshness, safety, and value.

In conclusion, jar PET preform moulds are indispensable components that drive excellence, efficiency, and innovation in the packaging industry. With their precision engineering, versatility in design, and commitment to sustainability, these molds enable companies to produce high-quality, durable, and environmentally responsible packaging solutions that meet the needs and expectations of consumers and businesses alike. As the demand for innovative and sustainable packaging continues to grow, jar PET preform moulds will continue to play a central role in shaping the future of the industry, driving advancements and pushing the boundaries of what is possible in packaging design and production.

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语