Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

Injection molding, also known as injection molding, is a molding method that combines injection and molding. The advantages of injection molding method are fast production speed, high efficiency, operation can be automated, variety of designs and colors, shapes can be from simple to complex, sizes can be from large to small, and the product size is accurate, the product is easy to update, and it can be made into complex shapes. Parts and injection molding are suitable for mass production and molding processing fields such as products with complex shapes.

At a certain temperature, the completely melted plastic material is stirred by a screw, injected into the mold cavity with high pressure, and cooled and solidified to obtain a molded product. This method is suitable for mass production of parts with complex shapes and is one of the important processing methods.

Injection process

temperature control

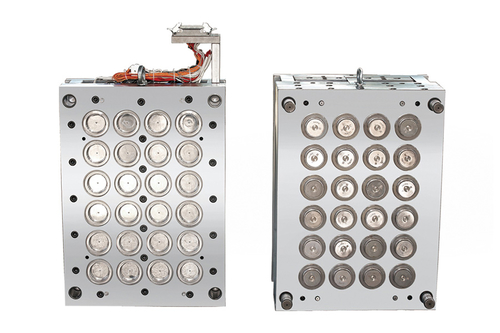

Injection molding equipment and molds

Injection molding equipment and molds

Barrel temperature:

The temperature that needs to be controlled in the injection molding process includes the barrel temperature, nozzle temperature and mold temperature. The first two temperatures mainly affect the plasticization and flow of the plastic, while the latter temperature mainly affects the flow and cooling of the plastic. Each plastic has a different flow temperature. For the same plastic, due to different sources or grades, its flow temperature and decomposition temperature are different. This is due to the difference in average molecular weight and molecular weight distribution. Plastics in different types of injection The plasticization process in the machine is also different, so the temperature of the barrel is also different.

Nozzle temperature:

The nozzle temperature is usually slightly lower than the maximum temperature of the barrel. This is to prevent the "salivation" that may occur in the straight-through nozzle of the melt. The temperature of the nozzle should not be too low, otherwise it will cause the premature solidification of the melt and block the nozzle, or the performance of the product will be affected due to the premature solidification of the material injected into the cavity.

Mold temperature:

The mold temperature has a great influence on the internal performance and apparent quality of the product. The temperature of the mold depends on the crystallinity of the plastic, the size and structure of the product, performance requirements, and other process conditions (melt temperature, injection speed and injection pressure, molding cycle, etc.).

Pressure control

The pressure in the injection molding process includes plasticizing pressure and injection pressure, and directly affects the plasticization of plastics and product quality.

Plasticizing pressure:

(Back pressure) When using a screw injection machine, the pressure on the top of the screw when the screw is rotated and retreated is called the plasticizing pressure, also known as the back pressure. The size of this pressure can be adjusted by the overflow valve in the hydraulic system.

In injection, the size of the plasticizing pressure needs to be changed with the design of the screw, the requirements of the product quality, and the type of plastic. If these conditions and the speed of the screw are the same, increasing the plasticizing pressure will strengthen the shear Function, that is, it will increase the temperature of the melt, but it will reduce the efficiency of plasticization, increase the reverse flow and leakage, and increase the driving power.

In addition, increasing the plasticizing pressure can often make the temperature of the melt uniform, the mixing of the pigments uniform, and the gas in the melt can be discharged. In general operation, the decision of plasticizing pressure should be as low as possible under the premise of ensuring good product quality. The specific value varies with the types of plastics used, but usually rarely exceeds 20 kg/cm².

Injection pressure:

In the current production, the injection pressure of almost all injection machines is based on the plunger or the top of the screw to the plastic

The applied pressure (converted from the oil pressure) shall prevail. The role of injection pressure in injection molding is to overcome the flow resistance of the plastic from the barrel to the cavity, to give the molten material the rate of filling the mold and to compact the molten material.

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语